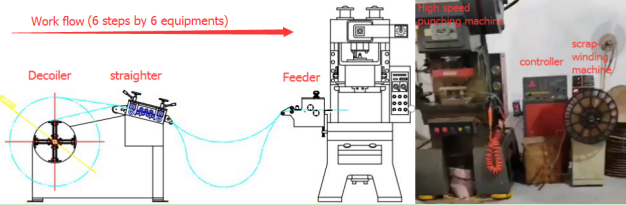

■ Decoiler:

Working Flow:

1) Discharge the inner axis out of the decoiler, then insert it into the steel coil.

2) Carry the steel coil together with the inner axis to the decoiler, install the axis on the frame of decoiler.

3) Use the hand wheel, to expand the inner axis, make the axis tighten the inner diameter of steel coil.

4) Release the brake of decoiler, make the coil sheet run out.

■ Straighter

1. After the material is corrected by this machine, it is smooth and smooth without indentation, and does not damage the surface of the material. It is suitable for various metal plates.

2. The machine adopts Japanese electromagnetic contact switch and electronic parts, which has few failures and long service life.

3. This machine can be used alone, and can be used together with MT type, MTD type, MTDM type automatic feeding rack, and the effect is good.

4. Rolling chrome plating, very durable and extremely long life.

■ Feeder

1.High-precision feeding: For high-tech industry, computer closed-circuit feedback control system, ensures accuracy within ±0.03mm

2, stage feeding function: can input 20 sets of different feeding lengths, each group provides 999 times of punching times, to meet the processing and production of special products (optional)

3, personalized manual mode: can input the appropriate 3 segment manual speed, making it easier for the user to operate, accurately put the material into the mold and locate

4, high efficiency relaxation device can meet the relaxation needs of high speed stamping

5.Feeding length setting: directly input the feeding length on the control panel to achieve the required feeding distance.

6. Feeding mechanism: The roller adopts hollow type, light weight, small rotary inertia, surface hardness HRc60 key hard chrome, wear resistance and long service life.

7, restore the original color of the device, beautiful and durable, stainless steel protective cover is more grade

■ High spped punching machine

■ Controller

■ Scrap-winding machine

Length: 205mm

Weight: 0.3Kg

Stripping(0.25-6.0mm2)

Cutting(0.25-6.0mm2)

Crimping terminal (0.5-6.0mm2)

new type press plier,adopt the principle of using the best leverage to effectively handle the design.Although the short and compact structure,especially in the larger horizontal pressure to the cross section of wire,the operation will be very effective.

Applicable for non-welding,complied with the atandard electrical connection.

The design of accurate crimping moulds and complete locking(Self locking and releasing mechanic unit)ensure high of criming quality when crimping repeatedly.

Accurate adjustment has been made before leave factory.

For surge connector

Production line

Naked terminals

Naked terminals on reel

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.