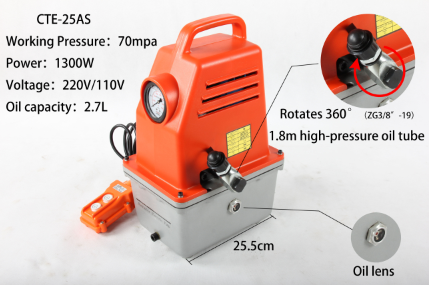

PART NO.: CTE-25AS

WEIGHT: 17.5KG

VOLTAGE: 220V

SIZE: 255*190*420MM

MAX OUTPUT: 700KG/CM2

FLUX(LV/HV): 3.5L/MIN, 0.52L/MIN

ROTATE SPEED: 2800RMP

WORKING PRESSURE(LV/HV): 0-20KG/CM*2, 20-700KG/CM*2

POWER: 1300W

OIL VOLUME: 2.7L

PHASE POSITION: UNIPHASE

OIL TYPE: #15 WEARPROOF HYDRAULIC MACHINE OIL

ACCESSORY: ONE PIECE OF 1.8M LENGTH OIL TUBE.

1.0 THE PURPOSE AND PERFORMANCE

1. The pump can be used as instruments of various hydraulic pump.

2. The pump after be equipped with other hydraulic tools, capable of lifting, pressure-type, bend, bend row, straightening, cutting, assembly, disassembly and many other work. Reduce the labor intensity and improve work efficiency.

2.0 HOW TO USE

1. Open the filler before use, the electric pump and power connections before oiling, then press down the black button which next to the motor to open, press the manual operation switch (up), after a few air pressure, press the manual operation switch (down), turn off the motor, connected to tubing. (The pressure should not exceed 63Mpa when air pressure, in order to avoid damage)

2. Open the motor after the pump connect with the equipment, and placed the operation valve in pressurized position after the motor rotates 1-2 minutes, this moment the hydraulic oil come into the cylinder to perform the work, and the output of the hydraulic oil will increases with the load on their own booster until 63Mpa.

3. The oil pump regular working temperature between 10℃~50℃,when find the oil temperature≥70 ℃ should stop using after continuous working under high pressure, let it self-cooling before use.

4. The pressure of the relief valve and safety valve have been set before the pump leave the factory, the user can not arbitrarily increase the pressure,could only reduce it according to the actual working pressure, that can improve the life of the pump station.

5. The motor must have reliable grounding

3.0 OPERATION AND MAINTENANCE CONSIDERSTIONS

1. The pump use #15 hydraulic oil.

2. Air pressure is prohibited before oiling.

3. Oil storage capacity must be within the range above the oil window.

4. Everytime when refueling or change oil, must use 80(or more) mesh oil filter, it’s need to wash the tank when replace, every 6 months change the oil.

5. Regular working temperature between 10℃~50℃.

6. The air nut is required to open before starting the electric pump and turn switch to the unloading position

7.t he pump already adjustment before leave factory, can not arbitrarily increase or reduce the pressure, must use pressure gauge when need re-adjust.

8. Pressure tubing have 105MPA test. However, due to the aging of the hose easily, so users need to be inspected regularly, usually 6 months, if use frequently then 3 months, check with 87.5MPA pressure test if there have damaged, bulge,leakage, you can not use.

9. Bearings are generally cleaned every 6 months, add grease during assembly

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.