Company Advantages1. MKS heat shrink butt connectors is exclusively developed by utilizing proprietary electromagnetic handwriting input technology. The R&D of this product is market-based to cater more needs of writing or signing in the market. It is made in accordance with European environmental standards

2. The product has won unanimous praises from all customers and has a promising market prospect. The product has a big current carrying capacity

3. High energy efficiency is one of the biggest selling points of this product. It is manufactured using the advanced latest energy-saving technologies. It is an important accessory product used to realize the electrical connection

4. This garment is durable. There are chemicals or mechanical finishes being applied to the woven fabric to improve the durability, and/or utility values. It can be white, blue, yellow, red, green, etc. based on needs

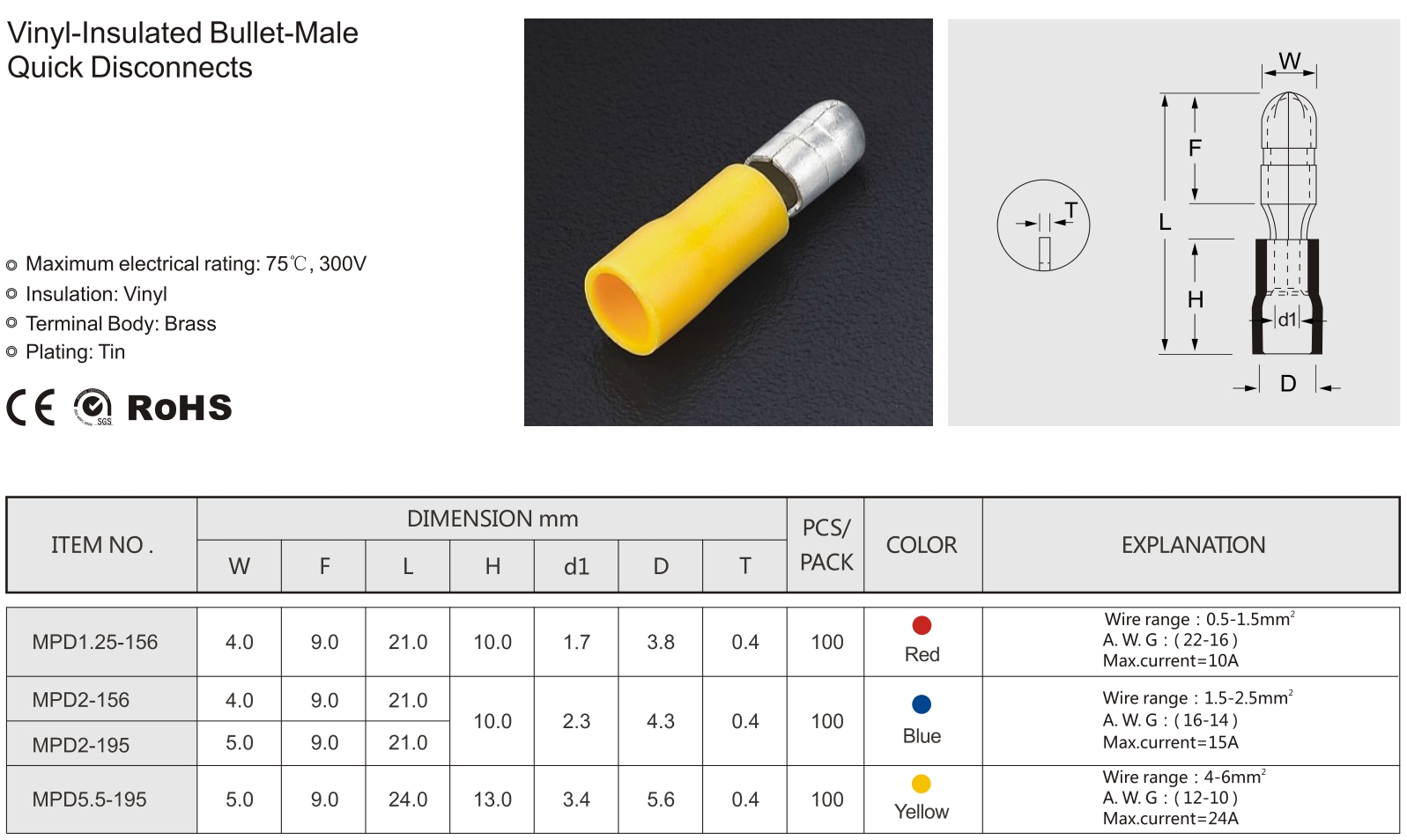

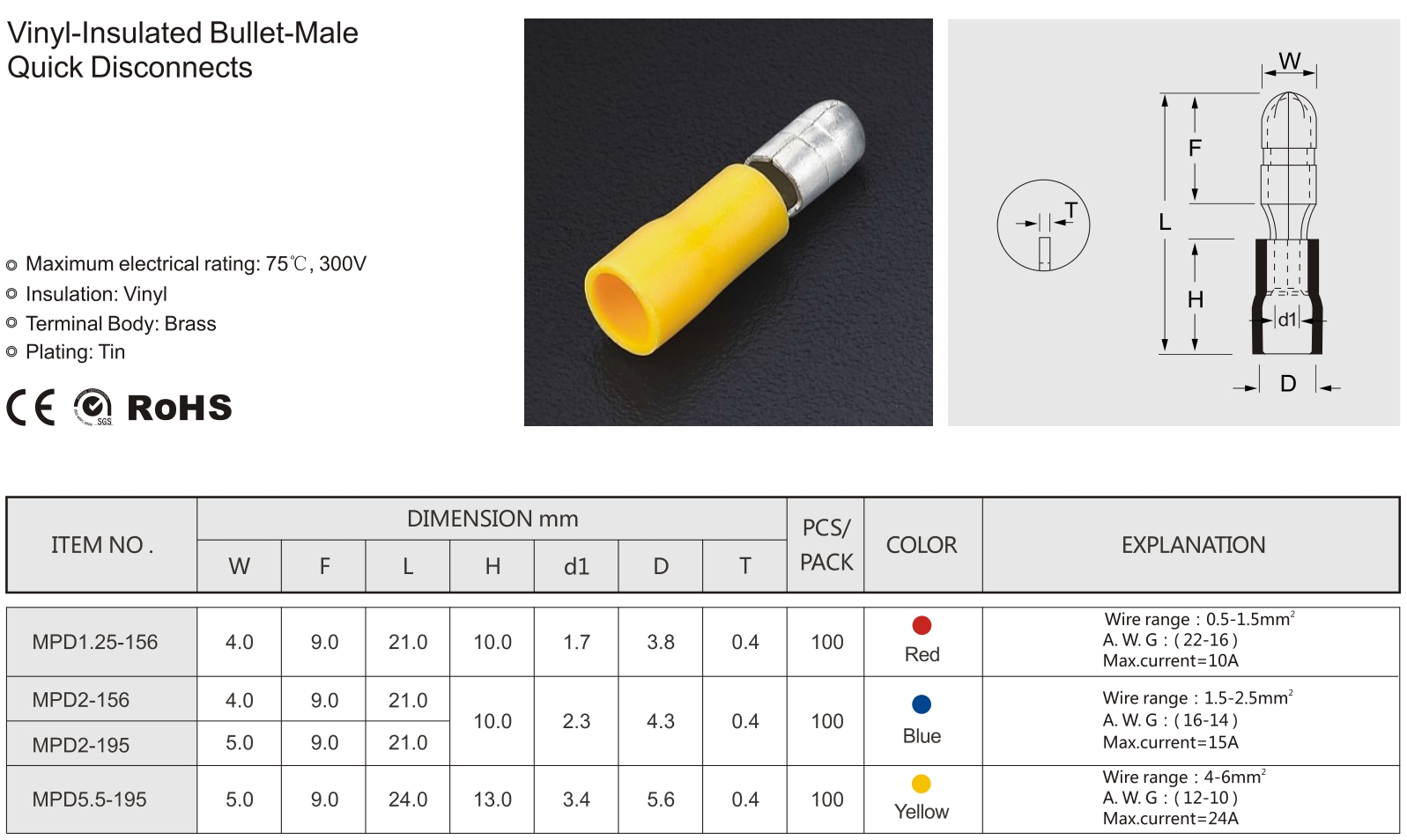

Product Name | MPD bullet male connector |

Terminals Materials | BRASS |

Plated | Tin plated |

Insulation Materials | PE |

Color | Red/Blue/Yellow/Black |

Max Voltage Rating | 600 volt |

Max Temperature | 75℃ |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

Company Features1. Over the years, we have strengthened our in-house sales and marketing divisions and started selling our products to customers and organizations in the global market.

2. Every year we ring-fence capital investment for projects that reduce energy, CO2, water use and waste that deliver the strongest environmental and financial benefits.