Company Advantages1. The best of raw materials, technology, equipment and personnel are used for the production of MKS electrical lugs . The product is less prone to aging

2. Also, the entire array of the offered product is designed for catering the varied demands of the clients. Heat resistance ensures its popularity in the market

3. The product has the advantage of stretchability. It has been stretched and strapped by the inspectors to check the elasticity. It can be white, blue, yellow, red, green, etc. based on needs

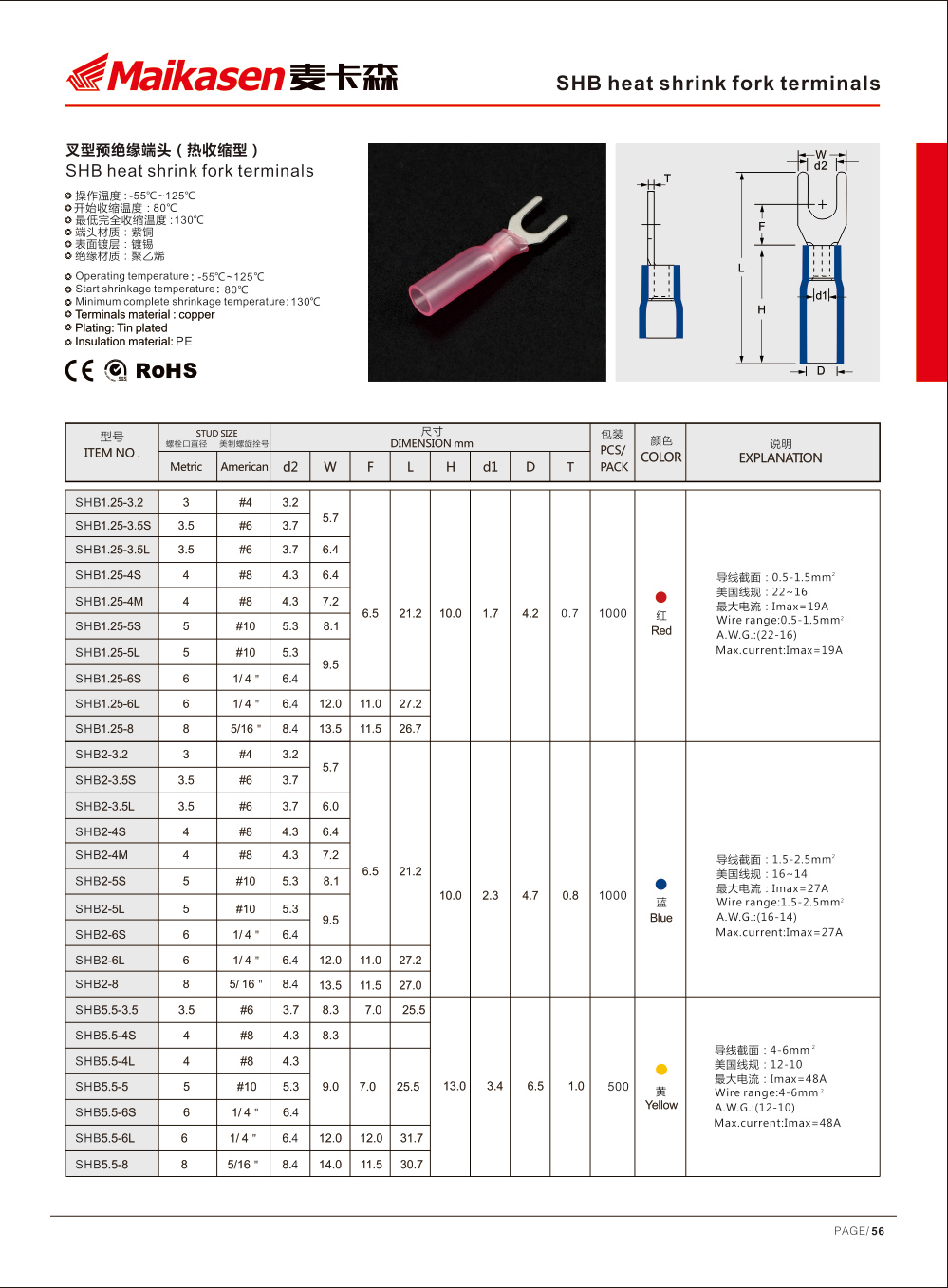

Product Name | SHB Heat Shrink Fork Terminals |

Terminals Materials | Copper |

Plated | Tin plated |

Insulation Materials | PE |

Color | Red/Blue/Yellow/Black |

Max Voltage Rating | 600 volt |

Max Temperature | 75℃ |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

Company Features1. That every part of the electrical connectors is strictly controlled more assures the exquisite performance of a product.

2. We are committed to offering great customer services to building their loyalty to us. We are working hard to have a positive impact on the customer base by giving timely feedback or response.