Company Advantages1. electrical lugs and copper lug are biggest strong points of our cable lug . Adopting PVC as one of the main materials, it has good stability and safety

2. Without containing petrochemical derivatives or synthetic preservatives, the product is popular with people for its silky textures, subtle and stunning colors. The product is less prone to aging

3. The product features both soft cushioning for foot protection and firmer cushioning for propulsion. The materials used in the forefoot and rearfoot part vary for different protection functions. The product won't rust even after being used for a long time

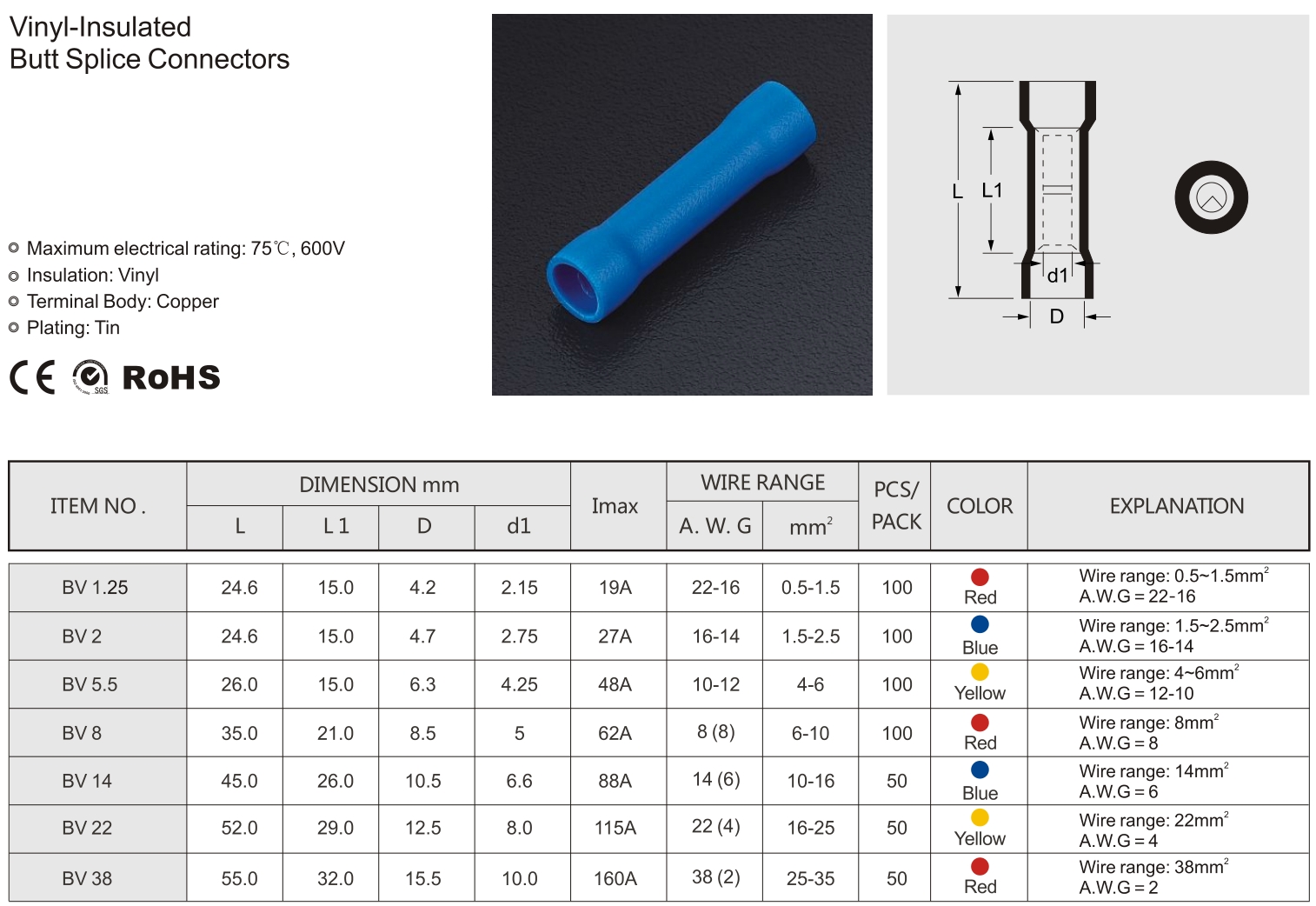

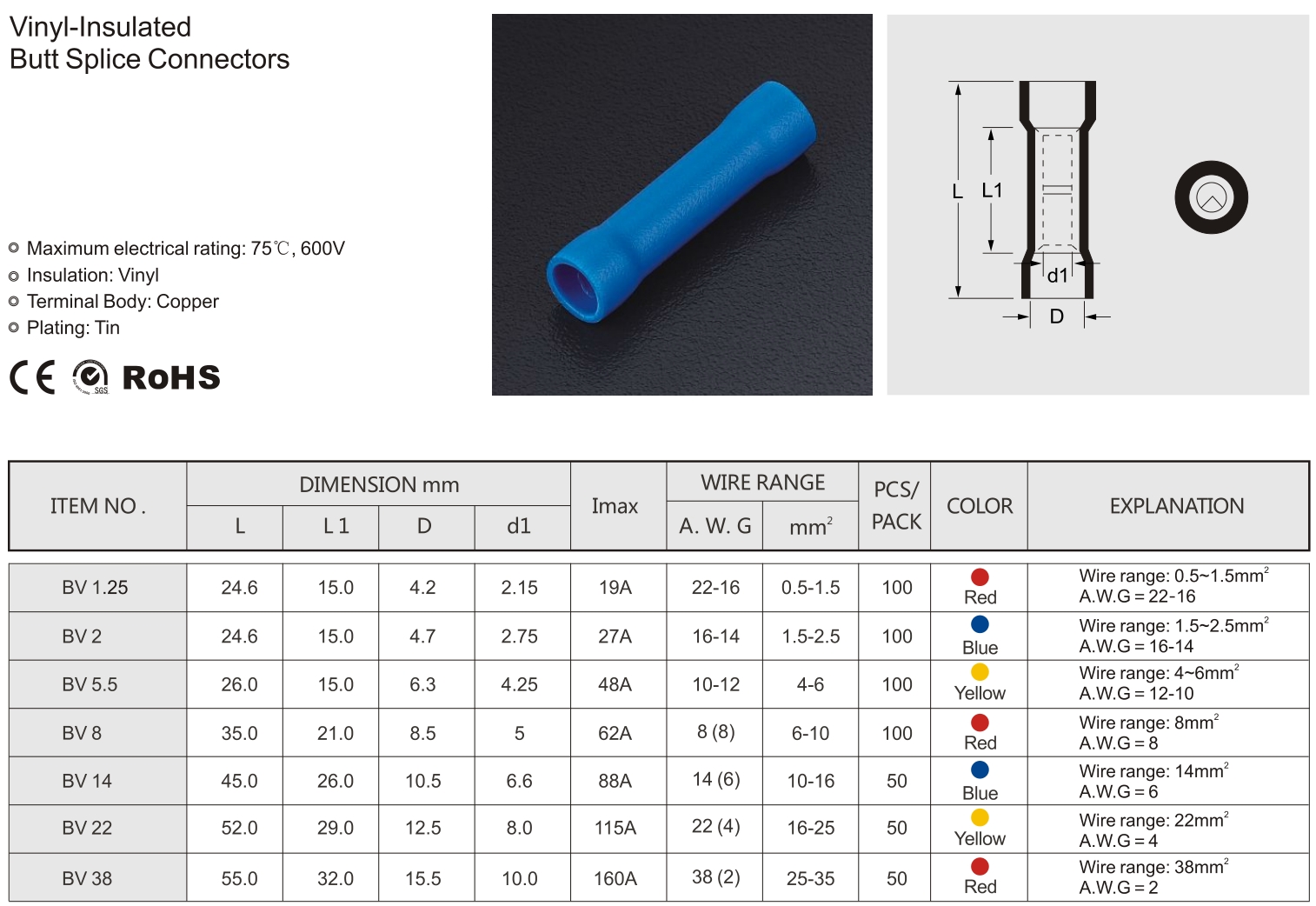

Product Name | BV RED VINYL BUTT CONNECTOR |

Terminals Materials | Copper |

Plated | Tin plated |

Insulation Materials | PVC |

Color | Red/Blue/Yellow/Black |

Max Voltage Rating | 600 volt |

Max Temperature | 75℃ |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

Company Features1. We develop, produce and distribute our products in-house, using the latest technology and the highest quality standards to provide finished products and ready-to-commodify products to our global partners.

2. We bear social responsibilities. We use our resources to assist our local communities in the areas of health, education, culture, and sports and will continue to focus on providing support to help these and other organizations be effective in achieving their goals.