Company Advantages1. The manufactured of MKS electrical lugs adopts various cutting-edge machines. They are high--speed precise CNC fabrication equipment and quality testing facilities such as height gauge and measuring instrument. It is made in accordance with European environmental standards

2. The product is easy to process and easily meets the comfort and distinct personality by adding printed images to it. It has a strong ability to resist salt, acid, alkali, grease, etc

3. This product features good moisture management. In the design phase, different degrees of sweating are simulated and corresponding parameters are determined (e.g. breathability, thermal insulation). It is widely used in the fields of computers, instrumentation, home appliances, electronics, railways, and so on

4. This product has good seams quality. Its seams are even, closely spaced, lying flat on its fabric and are not easy to burst. It can withstand the high temperature and low temperature as well

Product Name | RHB Heat Shrink Ring Terminals |

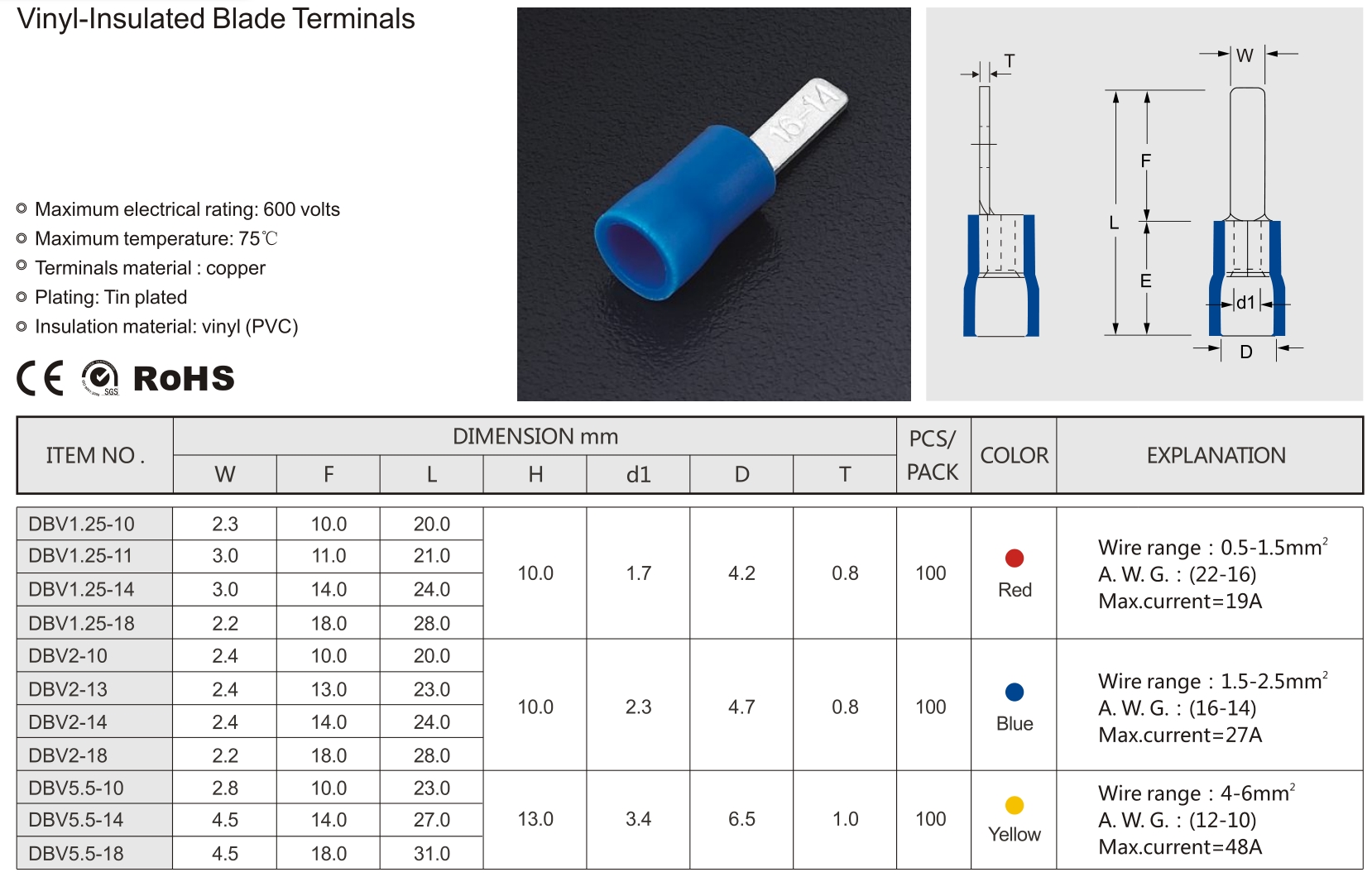

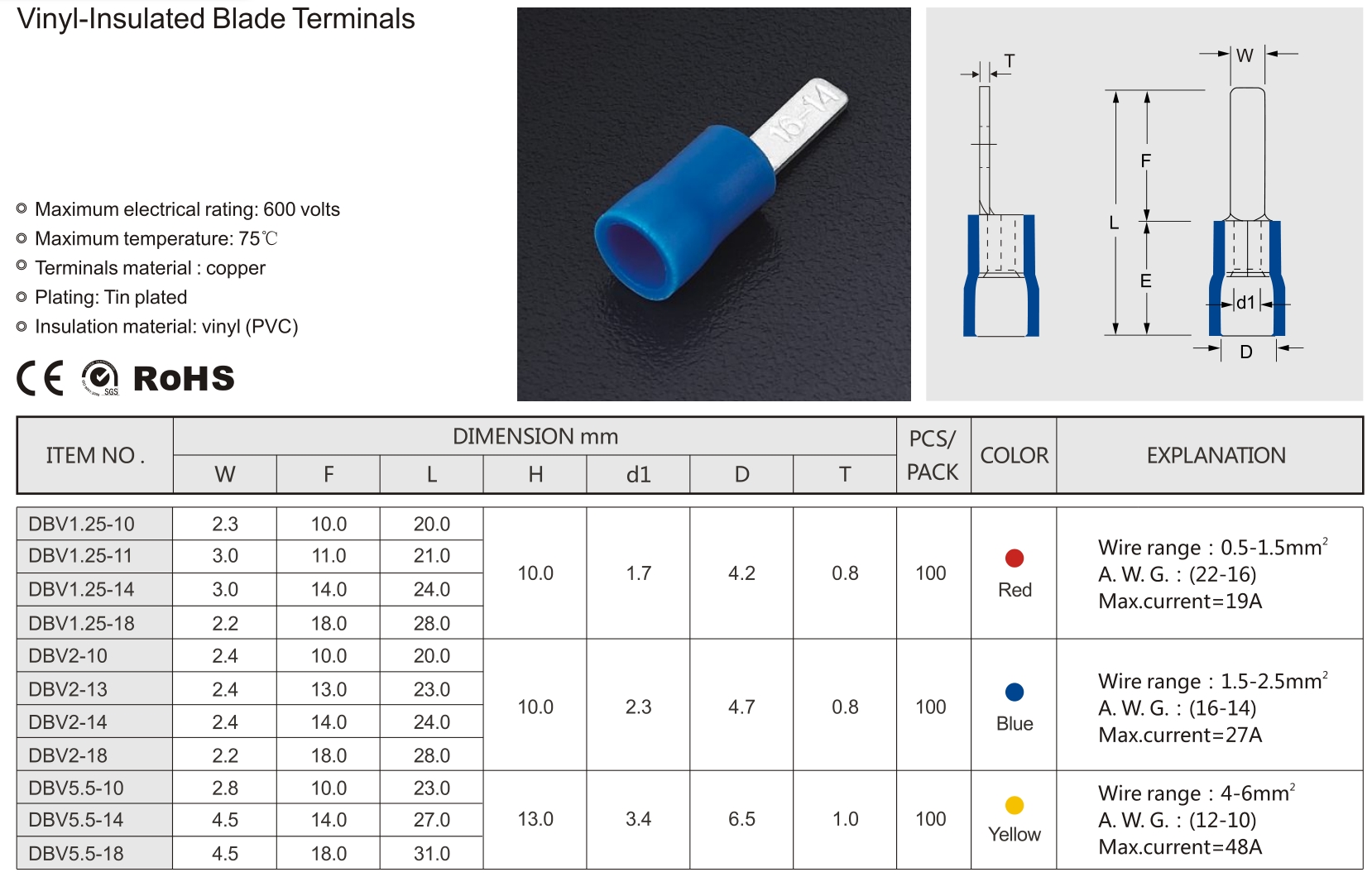

Terminals Materials | Copper |

Plated | Tin plated |

Insulation Materials | PE |

Color | Red/Blue/Yellow/Black |

Max Voltage Rating | 600 volt |

Max Temperature | 75℃ |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

Company Features1. YUEQING KAISEN TRADING CO., LTD's products sell well on international market.

2. Our company is globally engaged in product distribution. We have been expanding our client base across Asia, the Middle East, Russia, and Indian sub-continent.

3. Every battery terminals before delivery will conduct professional debugging to ensure it's perfect in function. Call!