Company Advantages1. The design of MKS indicator light takes many features into considerations. They are impact strength, abrasion resistance, easy molding, stability, and so forth. It is an important accessory product used to realize the electrical connection

2. Mainly due to its outstanding low maintenance rate, it requires almost no lamp replacement, which helps to save people money. It conforms to the standards of America, Japan, Germany, etc

3. terminal block is of indicator light, thus it has abroad applying foreground. It has passed the certification of CE

4. The application of terminal block can save the cost of customers and go a little further to simplify the usage methods. Packed with 5-layer corrugated paper, it is totally safe during transportation

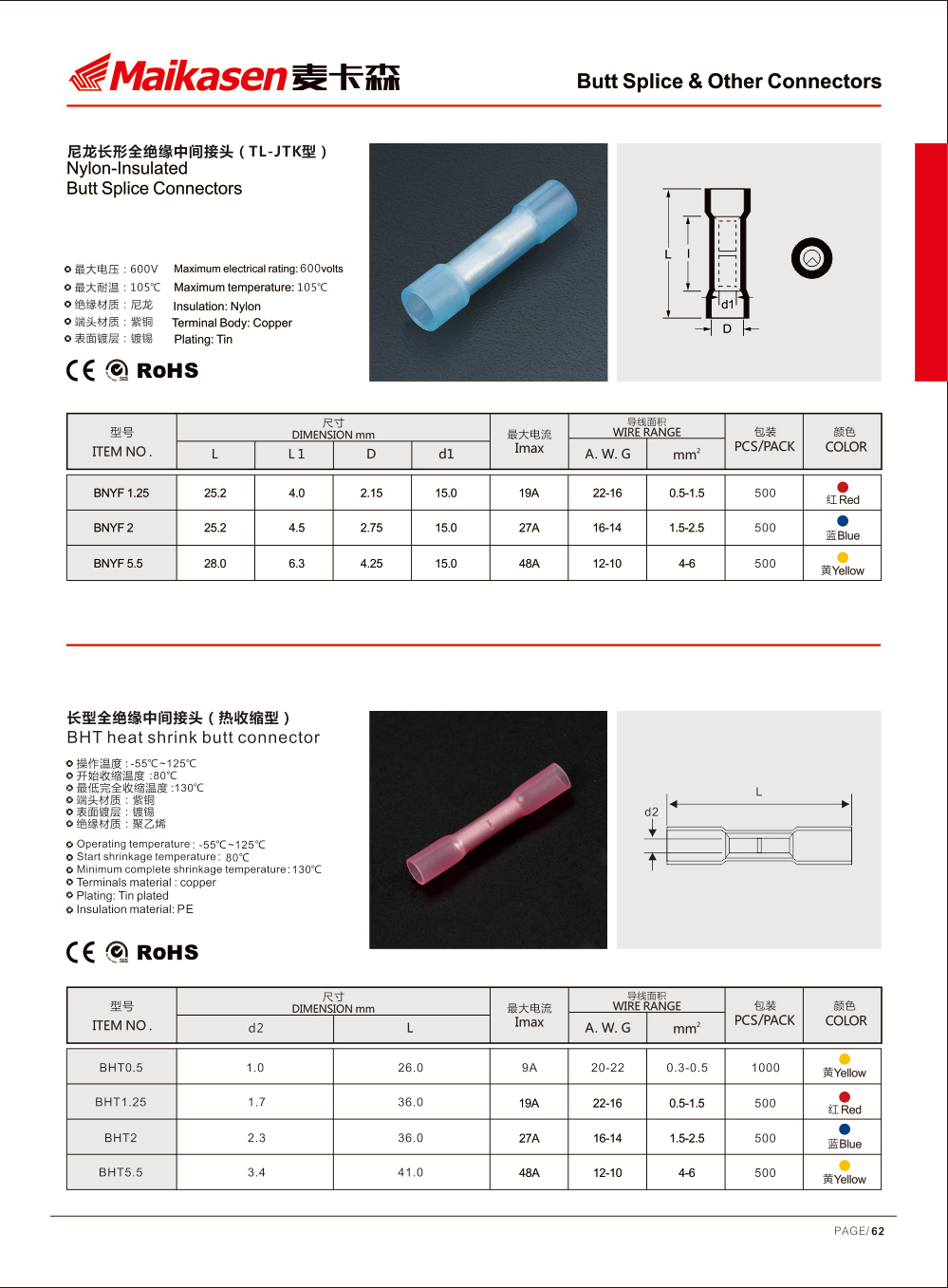

Product Name | BHT Heat Shrink Butt Connector |

Terminals Materials | Copper |

Plated | Tin plated |

Insulation Materials | PE |

Color | Red/Blue/Yellow/Black |

Max Voltage Rating | 600 volt |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

Company Features1. YUEQING KAISEN TRADING CO., LTD is mainly engaged in the production of terminal block . Our factory has the most efficient manufacturing machines. They can help simplify the production process, increase production efficiency, and produce higher quality products.

2. Our manufacturing plant has equipped with well-controlled production lines. These lines are all controlled by the QC team. From product production, assembly, to testing, all these lines conform with strict quality management systems.

3. Our factory has advanced manufacturing equipment. The use of these machines means that all major operations are automated or semi-automated, thereby increasing the quality of the product. It is a great goal for MKS to aim at being a cable lug supplier. Contact!