Product Description

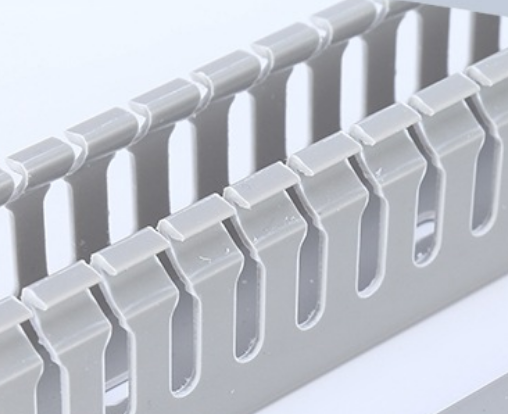

-PVC25*25 is made of PVC material. -High quality PVC material.flexible and not easy to break,burr free. -The groove and cover are closely fitted.tightly buckle -The size of outlet hole and installation hole is fixed.Easy to assemble and disassemble

Product Parameters

Name | PVC cable duct |

Material | PVC |

color | Grey(white and blue available) |

Length | 2meter/pc |

Voltage | 600V |

Width | 25mm |

Height | 25mm |

Q/P | 4/6 |

Package | 100meter/carton |

Product Details 1 Best material,good manufacture,burr free. Product Details 2 Flexible and not easy to break, Product Details 3 groove and cover are closely fitted

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.