Application: terminals are parts used to realize electrical connection, It’s classified into the category of the connector in industry. Terminals are applied for the convenience of wire connection, it is actually piece of metal sealed inside the insulated plastic, with holes at both ends and cables can be inserted, and screws are used to tighten or loosen. For example, two cables, sometimes need to connect, sometimes need to disconnect, and we can use terminals to connect them, and disconnect at any time, without welding them or intertwined, which is very convenient.

Abstract

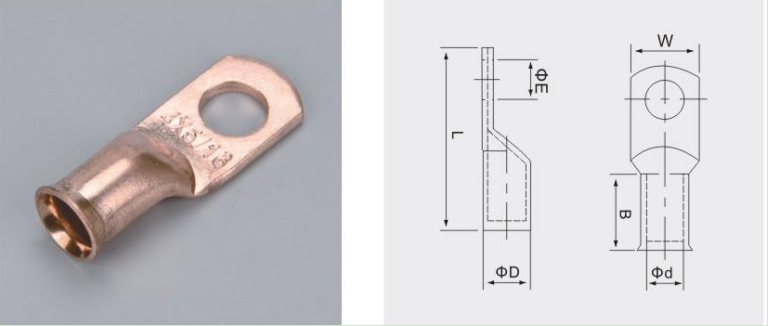

The utility model provides a bell mouth copper pipe terminal including an end face, an inclined plane and a tail which are disposed in an integrated mode. The inclined plane is disposed between the end face and the tail and provided with a peephole; the end face is provided with a threaded hole; and the upper portion of the tail is a bell mouth, the lower portion of the tail is a circular pipe, and the upper portion and the lower portion are disposed in an integrated mode. According to the bell mouth copper pipe terminal, the peephole is disposed in the inclined plane based on a present terminal, to make it convenient to check that whether a wire is inserted in the bottom or not; and the tail is stamped in to a bell mouth to make it convenient to thread a wire.

Features

Ideally suited to finely stranded flexible cable

Material: Oxygen free high conductivity annealed copper

Standards: AS/NZS 4325.1 ; IEC 61238-1:2003

Temperature Range: -55°C To 155°C

Suitable for fine strand conductors

Bellmouth makes insertion easier

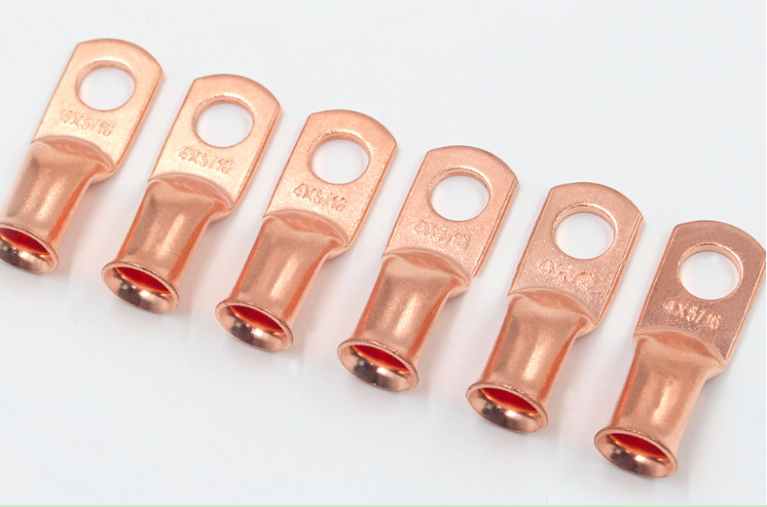

Copper compression lugs with a bell mouth entry to the barrel. The flared entry is designed to funnel fine stranded flexible conductors used in automotive, marine and welding cables. Hellermann Tyton bell mouth terminals are made from seamless 99.9% seamless copper tube extrusions, the connectors are formed, annealed, and finally electro tin plated. The tube wall thickness and relative inside and outside diameters are specific to Australian and New Zealand standards and suit Australian metric compression tooling. For ease of identification the conductor size and stud size is stamped on the lug palm.

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.