MKS-3 AUTOMAITC TERMINAL LUGS BRAZING MACHINE

一.Before starting up:

(1) Before starting up,make sure nice ground connection.

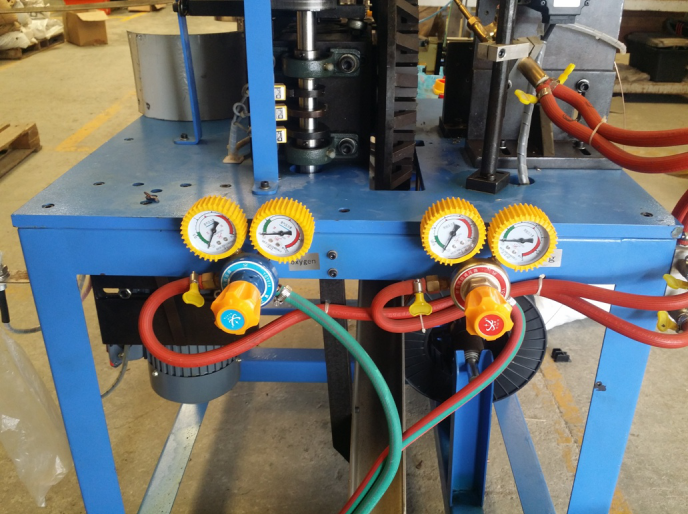

(2) Check the air pressure, make sure it is 60 psi-1--psi(4-7KG/CM2).

(3) Check oxygen,ethyne,make sure well connection,no leaking, then ignite the welding gun.

二.During operating:

(1) During operating,make sure all the workpieces sent to the right place and smoothly sent.

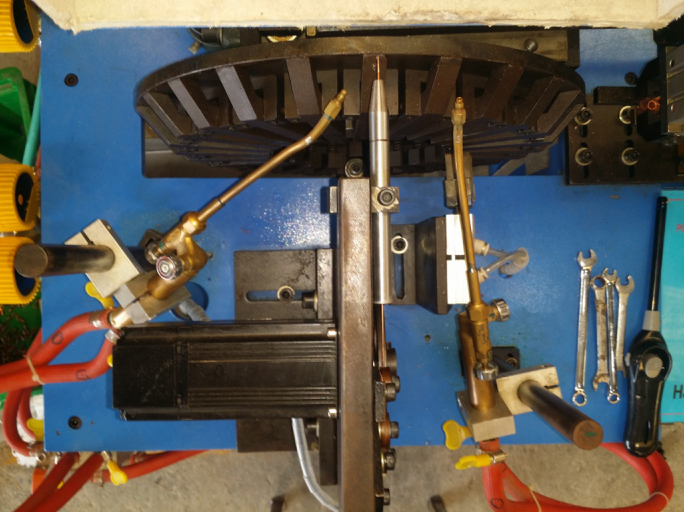

(2) If the work piece cant be weld or cant be weld well, adjust the acetylene gauge,oxygen gauge,or adjust the power level of the welding gun. Adjust the length of the solder wire(the length of the solder wire is controled by dial switch, original “00” is 0.5mm length,pressing single digit one time means +0.1mm, for example: number “07” means 1.2mm. ).

(3) If the workpiece cant be sent correctly to the right position, try adjust the yellow proximity switch behind the turntable. Including:

1. Adjust the actuation time of the pneumatic finger.

2. Adjust the Manual operating time of the turntable clamp.

3. Adjust the operating time for transporting solder wire.

一.After shutdown.

(1) Turn off the main power.

(2) Turn off the air pressure gage of the regulation group.

(3) Close the oxygen, ethyne.

二.Safety precautions.

(1) When the machine is operating, the forbidden part is putting hands or other things near the turntable and robot hand.

(2) Dont open the distribution box and enclosure at Back of the machine.

(3) With no professionals, It is better not to adjust the yellow proximity switch.

Product Character:

Steady feeding length. Make sure no cracking.

One machine match different awg.

One people can manage several machines at the same working time.

With no work piece, the machine will stop automatically.

Product Application

Automatic copper terminal lugs brazing machine are for the copper lugs braze

Cost-effective solution for terminal production – automatic solder terminal with sliver brazing alloy. One machine assembles for different terminal size. High soldering speed with programmed operation. Make soldering be productivity and quality, with minimum land space and labor. The leading terminal makers specify the UNIQUE soldering machine in terminal production.

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.