Product Parameters

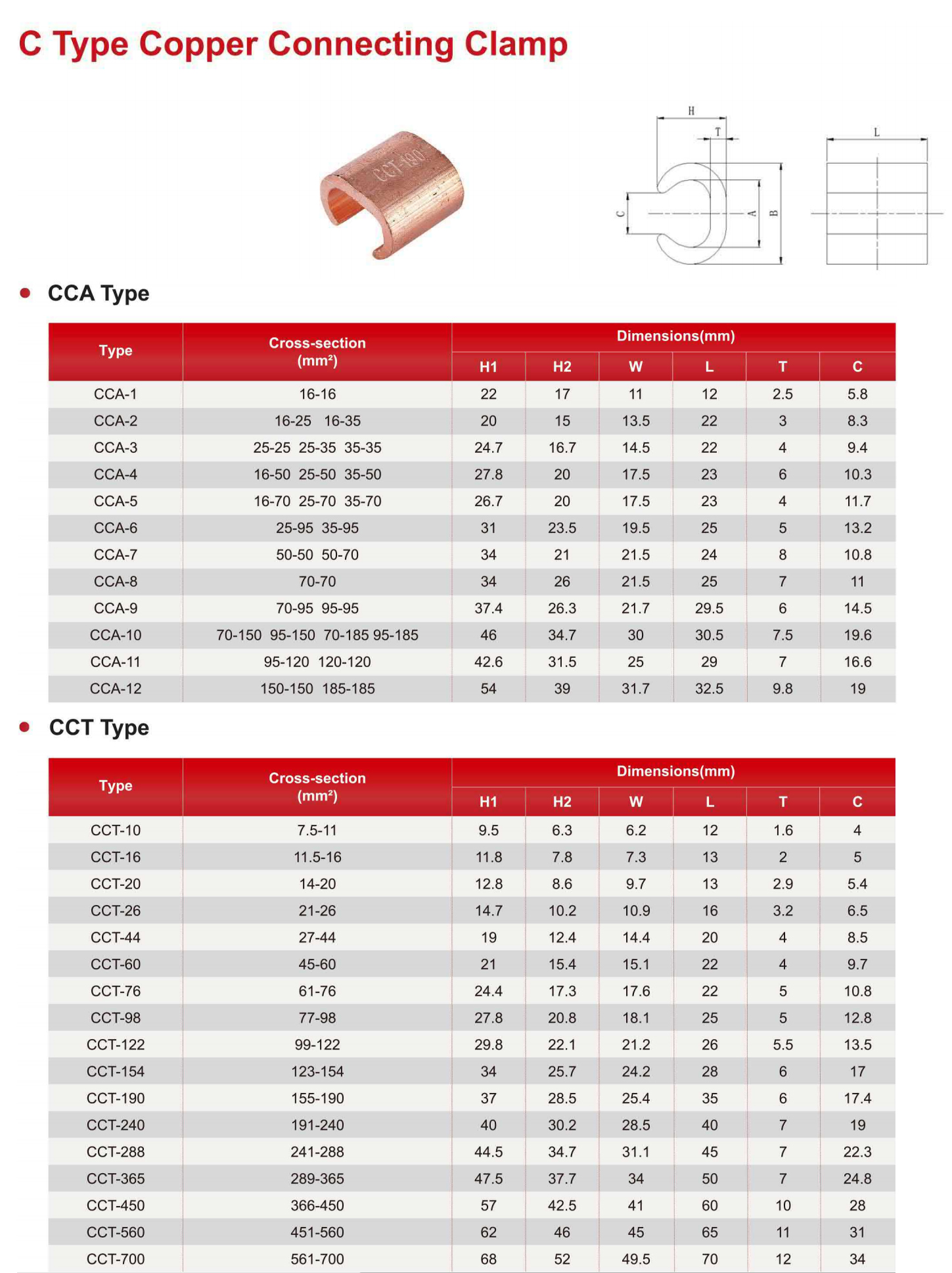

Product Name | C Shaped Tin Plated Clamp Electrics Copper Cable Clamps |

Terminals Materials | Copper |

Plated | Tin plated |

Insulation Materials | non |

Color | YELLOW |

Max Voltage Rating | 600 volt |

Max Temperature | 75℃ |

Max Current Rating | 19A |

Wire size | AWG 22~16, 0.5~1.5mm2 |

Certificate | CE/Rohs report |

Usage | Connecting Cable |

Special | Free Sample |

An electrical system is only as reliable as its conductors and conduit systems & fittings which provide unsurpassed protection for wire and cables in the most demanding applications: power generation, robotics, food processing, refining, waste water treatment, rail rolling stock & trackside, infrastructure, offshore drilling, mining, wind turbines, solar panels, off-road vehicles and many more.

Our conduit & fittings offer solutions for:

m10 waterproof connector Products Show

Copyright © 2025 Yueqing Kaisen Trading Co., Ltd. | All Rights Reserved

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.