- Tape

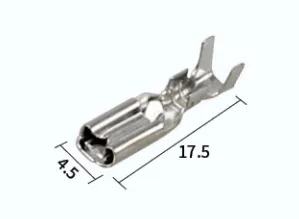

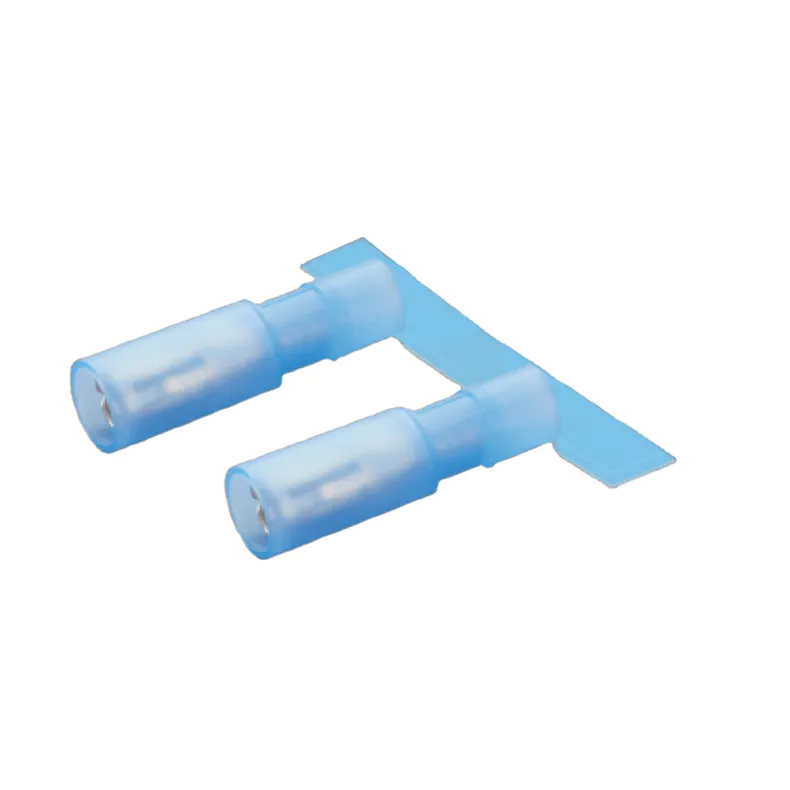

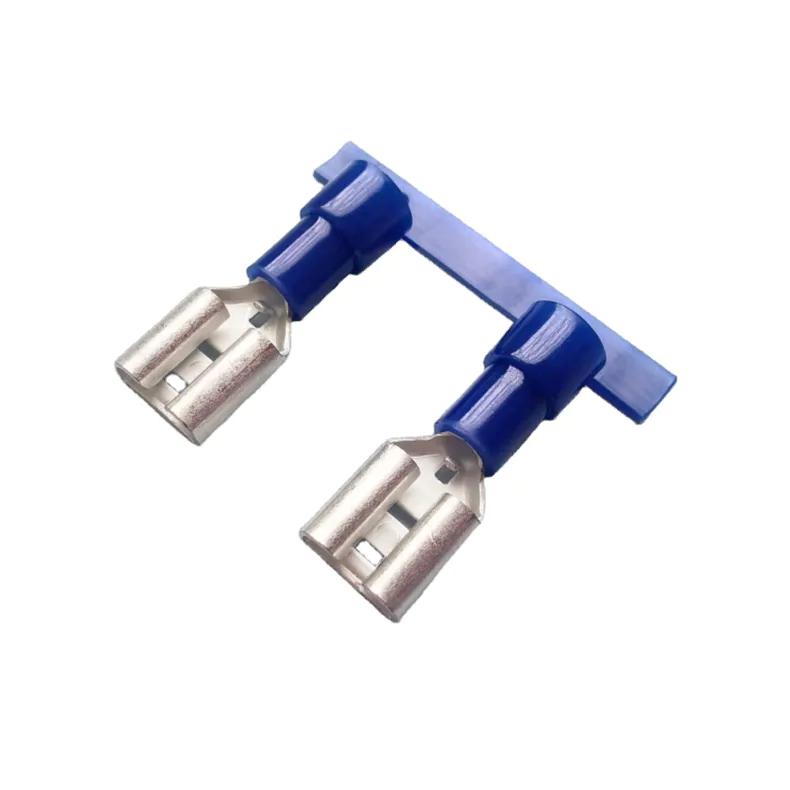

- Terminals & connetors

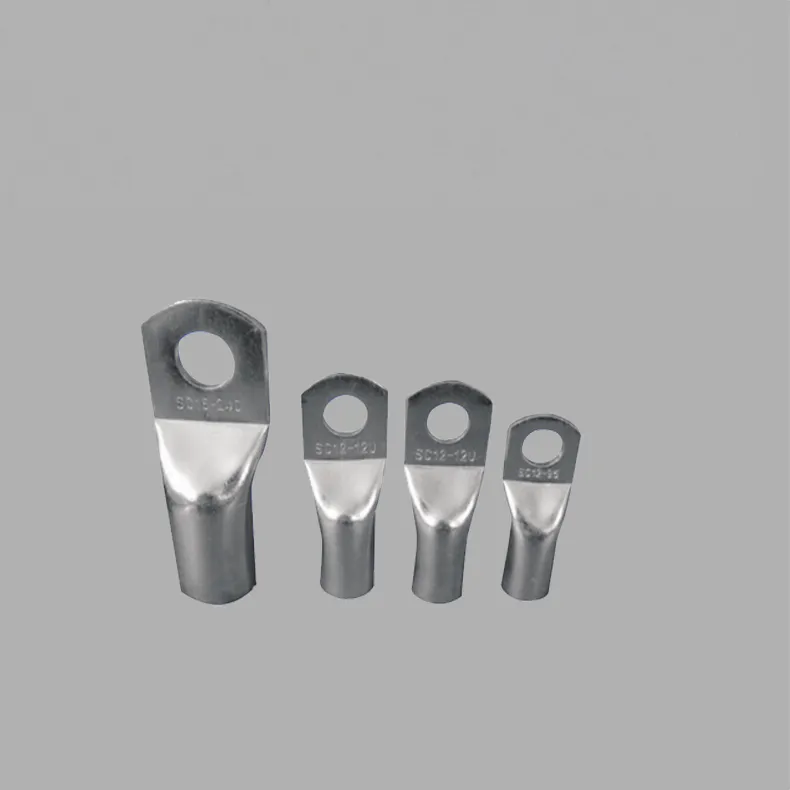

- Cable Lug

- Terminal block

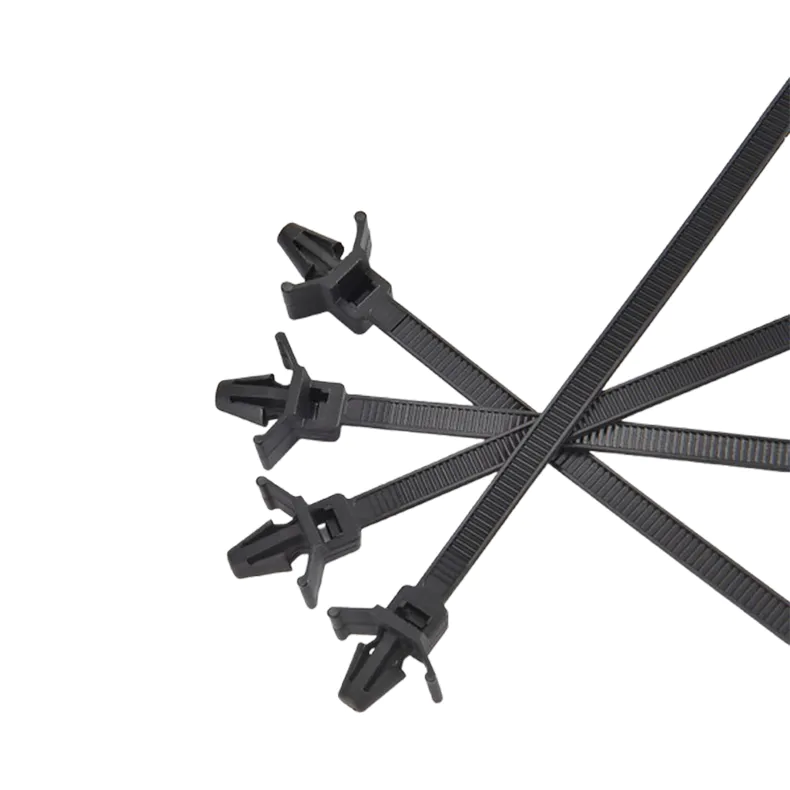

- Cable tie

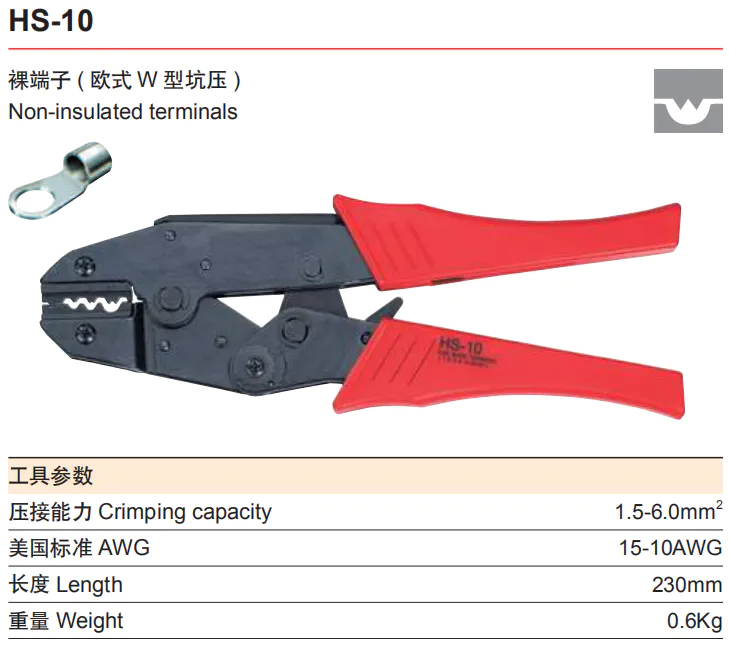

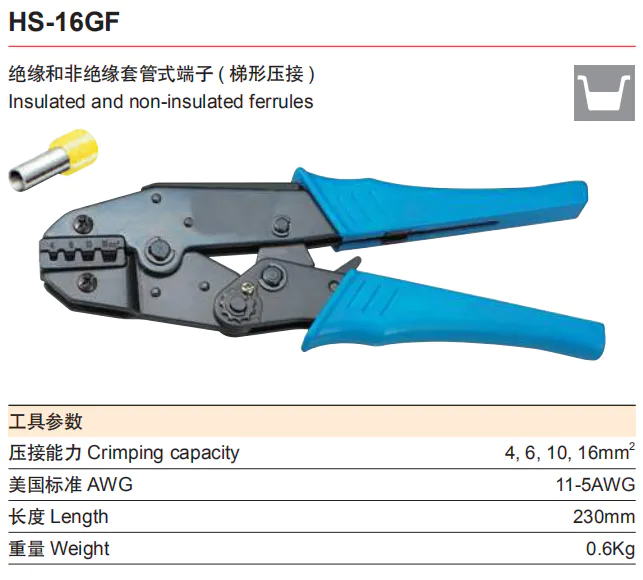

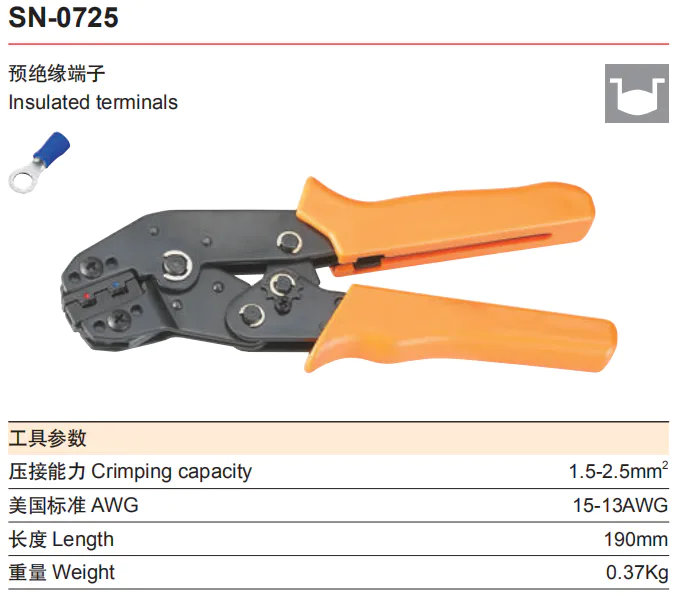

- Crimping tool

- Heat shrinkable tube

- Cable marker

- Junction box

- Cable gland

- Corrugated hose & spiral wrap band

- Wire duct

- Din rail

- Cable clips & mount

- Signal light

- Push button switch

- Standoff insulator

- Pet braided sleeve

- Industrial plug & socket

- Auto fuse

- Others